During the second shot in multi-component molding (MCM) process, the temperature distribution on the part insert will be affected by the residual temperature from the previous shot. Therefore, in order to attain accurate mold filling analysis results, the temperature distribution of the previous shot should be considered in the simulation analysis of the second shot. Moldex3D allows users to import temperature distribution information of the previous shot to the run of the second shot. Thus, the analysis results such as pressure distribution and warpage will be more consistent with the reality.Â

Setting

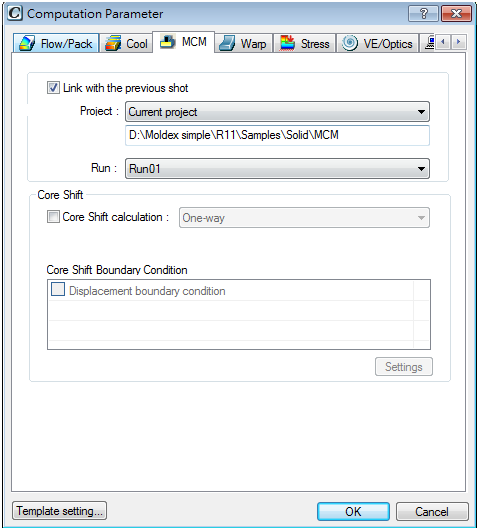

Start by opening the computation parameter dialog. Under Tab MCM, tick Link with previous shot and specify the part insert data of the project and the run number.

MCM Demo

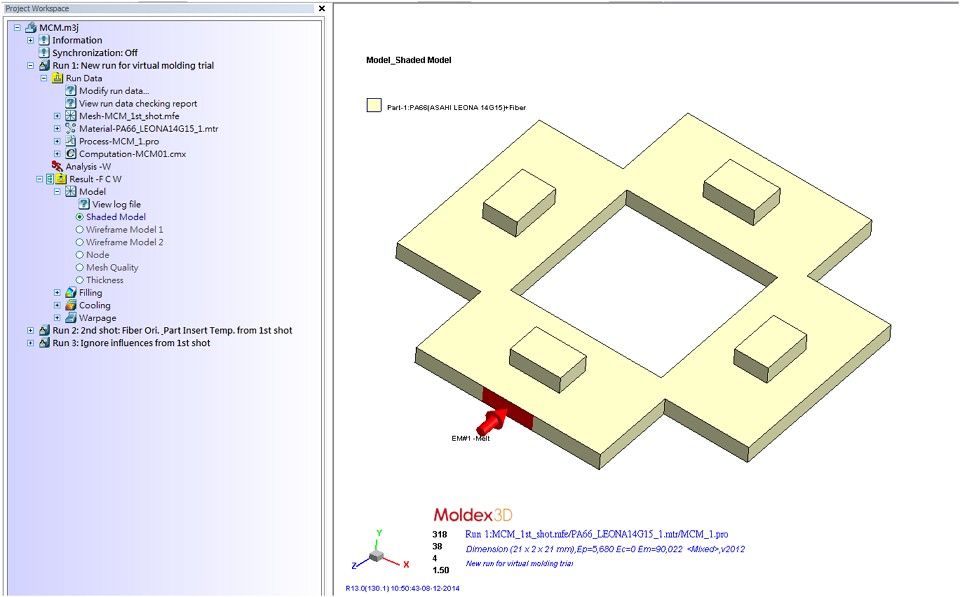

Step 1. Finish the simulation of the first shot.

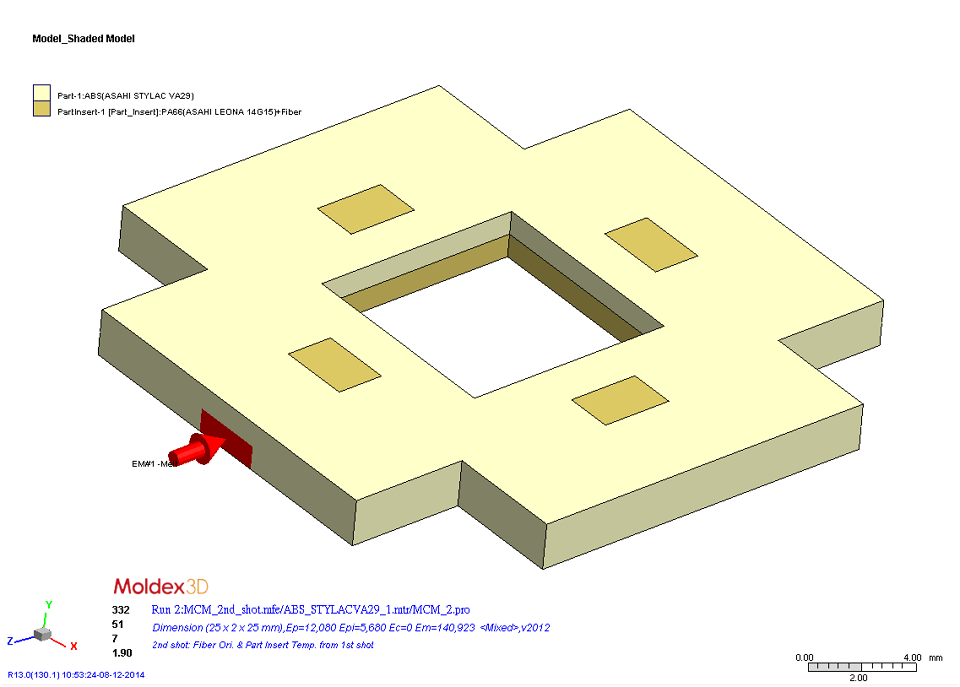

Step 2. In the second shot model, import the first shot geometry, and attribute it as a part insert. The material of the part insert should be the same as in the first shot. Refer to Setting as above to set computation parameters for the run considering the first shot temperature.

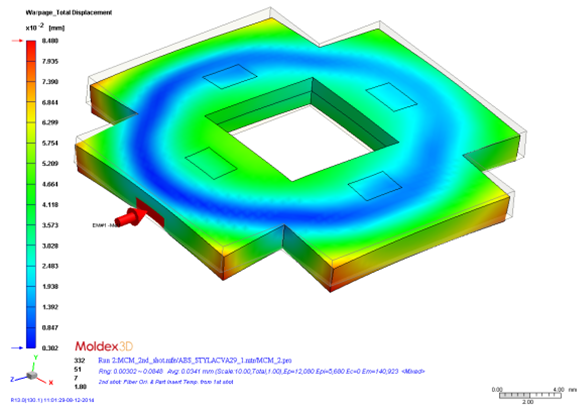

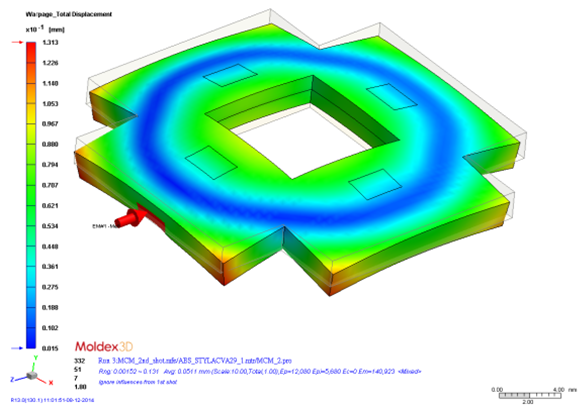

Step 3. The warpage results of both, considering and not considering the impact of the previous shot, are shown in the pictures below. The displacement of the first result is 0.085 ~0.003 mm, considering the impact of the first shot. The displacement of the second result is 0.13~0.0015 mm without considering the first shot temperature. As shown, whether considering the residual temperature from the previous shot or not in multi-material injection setting will impact the analysis results.

|

|

Considering the first shot temperature |

Without considering the first shot temperature |

Drive Pulley,Belt Drive Pulley,Underdrive Pulley,Belt Drive Herringbone Pulley

NINGBO TANSUO MACHINE MANUFACTURING CO., LTD. , https://www.tsjxidler.com